Title

Why

All the procedures routinely performed in the laboratory form a chain. The output of one procedure is input for other procedures. If one procedure is not carried-out correctly, the quality of all the other procedures in the chain is compromised. As explained in the previous activity it is necessary to standardize all the procedures performed in the laboratory to ensure that they are always executed correctly and in the same way, which in turn assures quality.

What

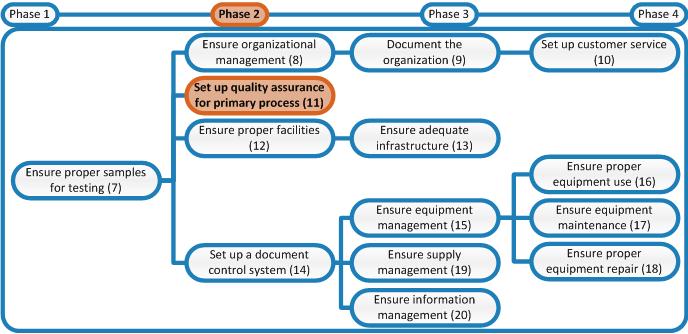

In the previous activity a list was made with all the SOPs that are needed to standardize the entire primary process. The aim of this activity is to develop all the SOPs in that list that have not yet been developed earlier.

How & who

Quality Officer and Laboratory Manager:

- Determine which of the SOPs listed in the previous activity need to be developed and which have already been developed.

- Laboratory Manager: determine for each SOP listed in the previous activity who will be the author. In phase 2 the document control system is/will be established. If you have already established this system: determine also who will be the reviewers and the authorizer (you, the laboratory manager, is in most cases the authorizer).

- Laboratory manager: assign the staff members identified as authors to develop the SOPs in compliance with the Master SOP. Do this in a SMART way: give deadlines to ensure timely completion of this activity.

- Quality Officer: assist staff members in writing SOPs according to the Master SOP.

- When an SOP is finalized: determine for which staff members this SOP is relevant. Include the SOP in the Read and Understand List and indicate which staff members have to read the SOP and sign off the Read and Understand List.

- Determine at which locations copies of the SOP have to be stored to facilitate easy access to the SOP for staff for which the SOPs are relevant.

- Present new SOPs in a weekly staff meeting. Explain the purpose of each SOP and for whom each SOP is relevant and who thus has to be read the SOP.

In phase 1 example Analysis SOPs and Equipment SOPs were already given in the activities where these SOPs had to be developed. In the right-hand column an example procedure SOP is given. In the Template Master SOP (also in the right-hand column) the template for a Procedure SOP can be found in Annex 1 (note that the Master SOP is also a procedure SOP).