Title

Why

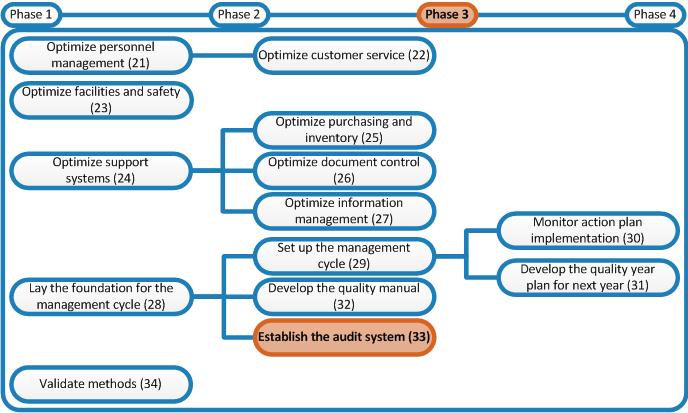

Besides monitoring the performance of examinations through internal quality control and external quality assessment (established in phase 2), the functioning of the quality management system also needs to be monitored to find possible weaknesses and opportunities for improvement.

What

The complete quality management system must be subjected to internal auditing. In internal auditing the documentation is compared with practice and with the standard. This way it is checked whether the procedures are indeed done as described in the documents (SOPs, Quality Manual, Biosafety Manual) and, vice versa: whether the procedures described in the documents are complying with the best method of performing them in practice. During these checks the compliance with the ISO 15189 standard is also monitored. The WHO Laboratory Quality Management System (LQMS) handbook provides background information on auditing (see right-hand column).

ISO 15189 requires that the main elements of the quality management system is audited every 12 months. It is advisable to also audit the examination methods at this frequency.

In phase 3 the internal auditing system will be set up. The first step is training: internal auditing must be performed by certified Internal Auditors. The number of Internal Auditors needed in the laboratory depends on the size of the laboratory and must be estimated by the laboratory manager him/herself. The number of staff members appointed as Internal Auditors should be sufficient to achieve auditing of the complete quality management system and all the examination methods every 12 months, without overburdening the Internal Auditors with too much work, creating an unacceptably high work pressure. Send at least the Quality Officer and one other staff member to training. This way the Quality Officer and the other trained staff member can form an audit team in which one does the interview and the other records what is said. Especially in the beginning it is difficult for one staff member to make notes and doing the interview at the same time. From a back-up perspective it is even better to have at least 3 Internal Auditors in case one person switches jobs or is otherwise not available.

How & who

Laboratory Manager:

- Estimate how many Internal Auditors are needed in your laboratory.

- Select staff members, among which should be the Quality Officer, to become Internal Auditors (you could select members of the former Quality Project Team that coordinated quality management activities in phase 1 before the Quality Officer was appointed).

- Find funding to support training of these staff members.

- Select an appropriate internal auditing course and send the staff members to this course.

- When staff members have completed the course, store copies of their training certificates in their personnel files.

- Create a Position Job Description of the position of Internal Auditor that describes the tasks and responsibilities of an Internal Auditor.

- Adapt the Personal Job Descriptions of the staff members that are now also in the position of Internal Auditor.

- Adapt the Authorization Matrix to include the authorizations of the position of Internal Auditor.

- Explain to all staff members in a weekly staff meeting the concept of internal auditing; explain what is done during internal auditing and why it is this done. It is important to explain that during auditing the quality management system is checked, not the performance of staff members that are interviewed (it is not a test). Often Internal Auditors tend to act or be seen as police officers and it is presumed that answering questions incorrectly leads to punishments of the staff members. This should not be the case and this should be made clear to all staff members. Present who the Internal Auditors are.