Title

Why

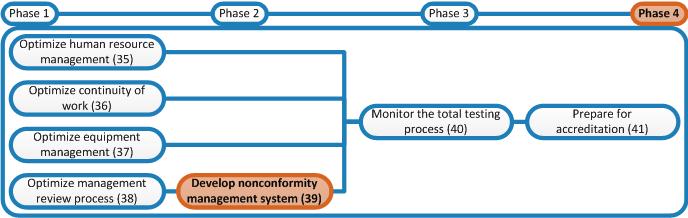

Failure mode and effect analyses (FMEA) on all the processes of the laboratory are one of the most important activities for continual improvement. FMEA is a process analysis that helps you to get insight in potential sources of nonconformities, the probability that they happen and the severity of the consequences if they happen, and it offers you the opportunity to prevent them.

What

Earlier in this phase the Quality Officer was trained in performing FMEA. In phase 2 flow charts were made of all the routine laboratory procedures. Perform an FMEA on each routine procedure for which a flow chart was made. Note that you can use these flow charts as aid in performing the FMEAs.

How & who

Quality Officer in collaboration with the heads of the sections/units in which the processes subject to FMEA are routinely taking place:

- Perform an FMEA on each procedure for which a flow chart was made in phase 2.

- Make a report describing all the failure modes, the probability of the failure modes happening, the severity of the consequences if these happen, and possible preventive actions, control steps and corrective actions that can be implemented for each failure mode. Do not limit yourself by including time or financial limitations: it is the task of the laboratory manager to decide which controls and actions are feasible and opportune. Submit this report to the laboratory manager.

Laboratory Manager:

- You will receive reports from the Quality Officer of FMEAs of different procedures routinely performed in the laboratory. In each report failure modes (possible things that can go wrong) are described, together with the severity of consequences when failure modes indeed happen and suggestions for preventive actions, control steps and corrective actions. It is your responsibility to decide whether the efforts of introducing preventive/corrective actions and control steps weigh up against the probability of the nonconformity happening and the severity of the consequences when it happens.

- Decide which preventive actions, control steps and corrective actions must be implemented in the laboratory.

- Make SMART action plans to ensure implementation of those preventive/corrective actions and control steps selected by you in the previous step. The actions should, amongst others, be the adaptation of SOPs for the procedures in which the preventive/corrective actions and control steps are implemented and the tutoring of staff members in implementing the actions and controls (explaining why and how the actions and controls are implemented).

- Submit the action plans to the Quality Officer and ensure that they are carried out.

Quality Officer:

- You'll receive action plans to implement preventive actions, control steps and corrective actions, that the laboratory manager has formulated based on the FMEA reports you have submitted earlier. Monitor the timely implementation of these action plans. Do this by adding the action points to the minutes of the weekly staff meeting. This way you can go through the action points every staff meeting and ask for their status of implementation. As the laboratory manager also attends these meetings the staff members that have not yet implemented action points after the deadlines can be forced by the laboratory manager to implement the action points as soon as possible.

- Archive the report of the FMEA in a new folder titled "FMEA".