Title

Why

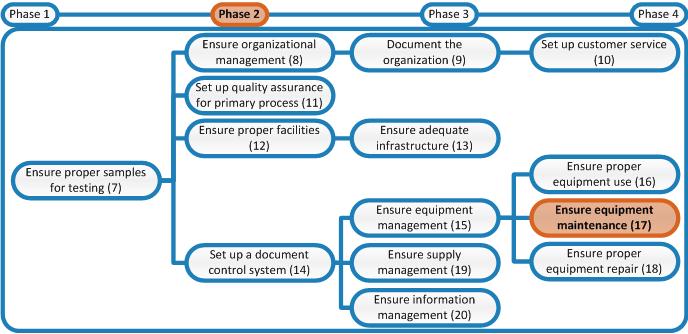

The first step in setting up a preventive maintenance and calibration system for equipment is the determination of the maintenance and calibration methods that are necessary for each piece of equipment.

What

Decide for each piece of equipment the maintenance and calibration methods. The way in which you organize maintenance (both internally and externally to the laboratory) for the equipment will depend on the complexity of the maintenance and calibration methods. If calibration and maintenance are easy to perform a staff member/Equipment Officer may perform the maintenance him/herself (with or without additional technical training). If the equipment is sensitive and maintenance/calibration is complex it is better to hire an external, specialized company to do the maintenance. It is also possible that the manufacturer offers maintenance and calibration services. [TB] Refer to Guidance for Countries on the Specifications for Managing TB Laboratory Equipments and Supplies for more information on more TB sepcific laboratory equipment maintenance and calibration.

Determine the following for each piece of equipment:

- The frequency and method of maintenance/calibration

- Whether maintenance can be done by the laboratory itself or must be done by an external specialized company

- When maintenance is done internally: if additional training is needed for the staff member assigned to perform this maintenance

- Which companies are suitable for maintenance/calibration of equipment for which the laboratory cannot perform maintenance itself

- The annual budget needed for maintenance

- The budget needed for additional training of staff for maintenance of equipment

How & who

Equipment Officer:

- Determine for each piece of equipment the optimal frequency and method of maintenance.

- Determine for each piece of equipment whether it is possible for the laboratory to perform this maintenance internally or that an external, specialized company should perform the maintenance

- Determine, for those pieces of equipment that are services within the laboratory, if additional training is needed for the staff member who is going to perform this maintenance.

- Determine, for those pieces of equipment that need to be serviced externally, the most suitable company that can perform this maintenance and calibration. If no certified maintenance or calibration company is available, investigate for the most optimal solution (e.g. training of a staff member to perform this maintenance, an arrangement with the supplier or manufacturer to ensure maintenance, etc.).

- Calculate the average annual budget needed for maintenance and calibration of equipment.

- Calculate the budget needed for training of a staff member to perform technical maintenance and calibration of equipment internally.

- Document all this in one overview for later use when the Equipment Maintenance Schedule is developed and launched. Submit this document to the laboratory manager so that he/she can start identifying funds.

Laboratory Manager:

- The Equipment Officer calculates the average annual budget needed for maintenance and calibration of equipment and the budget needed for training of a staff members to perform technical maintenance and calibration of equipment internally. Start identifying funds for maintenance and calibration of equipment and, if applicable, for training of a staff member to perform maintenance internally.