Title

Why

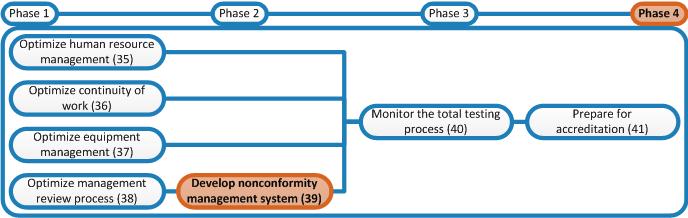

In the previous activity preventive actions, control steps and corrective actions were implemented in the laboratory to prevent and control nonconformities. These actions and controls were suggested based on a theoretical basis. It is important to investigate if they indeed help to prevent and control failure modes in practice. This is important because if the failure modes are still not appropriately prevented and controlled, this is a waste of efforts and resources and, even worse, the safety and quality of laboratory processes is still not totally controlled and assured.

What

Perform an internal audit focusing on preventive actions, control steps and corrective actions implemented in the laboratory following the failure-mode-effect-analysis (FMEA).

How & who

Quality Officer:

- Perform an internal audit focusing on whether each of the preventive actions, control steps and corrective actions implemented in the laboratory following the FMEA is helping to prevent and detect nonconformities.

- Submit the audit report to the laboratory manager.

Laboratory Manager:

- When you receive the audit report on preventive actions, control steps and corrective actions from the Quality Officer, develop an action plan to replace/adapt ineffective control steps and preventive/corrective actions for more feasible ones.

- Submit the action plan to the Quality Officer and ensure that it is carried out.

Quality Officer:

- You will receive an action plan following your audit report to optimize control steps and preventive/corrective actions. Monitor its implementation by adding the action points to the minutes of the weekly staff meeting. This way you can go through the action points every staff meeting and ask for their status of implementation. As the laboratory manager also attends these meetings the staff members that have not yet implemented action points after the deadlines can be forced by the laboratory manager to implement the action points as soon as possible.

- Pay extra attention in the following audits to see if the effectiveness of the optimized control steps and preventive/corrective actions has improved.