Title

Monitor transportation of samples

Why

Correct transportation of samples to the laboratory is crucial for the delivery of correct and quality assured results. Samples that have deteriorated due to bad conditions during transport to the laboratory will never lead to a quality result. Moreover, the samples also need to be packed in a safe manner to protect the courier and other persons involved in sample transport.

What

Continuously monitor the correct transportation of samples. Focus attention on:

- Safe transportation of samples: packed properly to protect the carrier, the general public, but also the laboratory.

- Timely transportation of samples: within the appropriate time frame.

- Transportation under proper conditions: within a temperature interval required to optimize sample preservation. The laboratory could encourage clients to use temperature logs that record the temperature throughout sample transport to check that the temperature has not become too high or too low.

If samples are received in a bad state due to incorrect transport, or if they are packed in an unsafe manner, the cause of the problem needs to be identified and appropriate corrective and preventive actions need to be undertaken.

How & who

Sample Reception Unit:

- Start to continuously monitor correct transportation of samples by checking if the criteria for transportation of samples as formulated in the SOP for Sample Collection are met for each sample. If bad quality samples are received, always follow these up by attempting to discover what has led to deterioration of the sample or the incorrect packaging. If the cause is found, try to develop preventive measures to prevent that more samples will deteriorate in the future due to this cause. For example: if a leaking sample is received at the laboratory because a wrong container was used, the client must be contacted to inform him/her about this and to instruct on the correct sample container to be used.

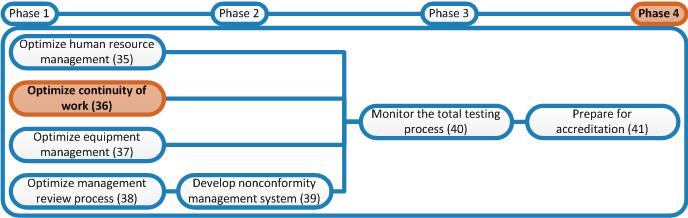

- Later in phase 4 to procedure for handling nonconformities must be established. When this is done, fill out a Nonconformity Form for every problem with transportation of samples. Describe that there was a problem with sample transportation, describe the problem and describe the corrective actions that were taken. Recording this helps you to get insight in the frequency of problems occurring in sample transport. For example: when a lot of samples are contaminated or all bacteria are dead due to long transportation time, recording this occurrence helps you to determine the scale of this problem and enables you to formulate specific corrective and preventive actions in attempt to resolve this problem. It subsequently helps you to see if these actions have helped to solve the problem (you should see a decrease in nonconformity forms reporting sample contamination due to long transportation time). Store the Nonconformity Forms in the folder "Nonconformities" (that will also be created in phase 4).