Title

Why

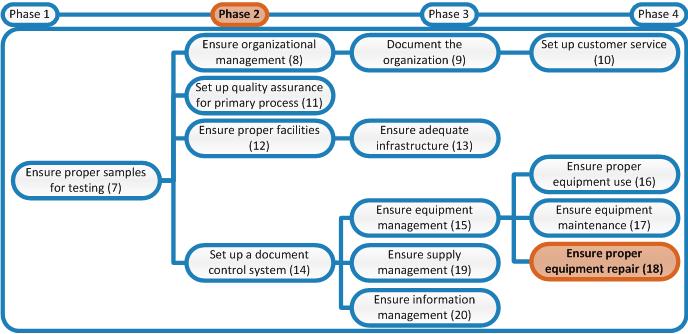

When equipment is broken and needs repair, it is highly important to eliminate the risk of the person performing the repair becoming infected with pathogenic organisms. Besides, it must be clear to everybody that the equipment is defect which prevents that people still try to use the defective equipment, creating potential hazards to the equipment, the person using it and the test result.

You have to be certain that equipment that is returned into service after being repaired is able to perform correctly and delivers good quality and true results.

What

Write an SOP that provides all the procedures that must be followed when a piece of equipment is defective; from disinfection and removal from the laboratory to returning into the laboratory following proper validation. Include in this SOP at least the following:

- Procedure for disinfecting the equipment, including specification of when it should be disinfected.

- Procedure ensuring that equipment is clearly labeled as defective directly after detecting that it is broken, preventing further use of the equipment. This label must also indicate if the equipment has been disinfected.

- Procedure for ensuring appropriate packaging when the equipment needs to be transported, preventing further damage to the equipment.

- Procedure for ensuring that adequate repair is done according to the SOPs in which the procedures for maintenance of the broken piece of equipment are described (including recording of repairs in the equipment files).

- Procedure that has to be followed when equipment is returned into service again after reparation: verification that the equipment is able to achieve the predefined performance requirements and that it is able to deliver a true and high quality result (which is called validation of equipment).

In the right-hand column you can find background information regarding equipment repair and maintenance from the WHO Laboratory Quality Management System (LQMS) handbook.

With regard to the last point: As the performance requirements differ per piece of equipment you cannot define these in the SOP. Therefore, include a form for recording that validation has happened. This form is similar to the equipment reception checklist (attached to the SOP for Procurement and Reception of Equipment): it is used to verify that the piece of equipment is able to achieve performance requirements formulated by you. Hence the form must have space allocated for formulation of performance requirements to which the piece of equipment must be tested and must comply with. Make sure the form guides the person validating the equipment through the whole process in a stepwise manner.

After finishing the validation the person should sign the form and give the form to the Equipment Officer for archiving in the equipment file. This form will be an appendix of the SOP.

How & who

Equipment Officer:

- Make an overview of contents to be included in the SOP.

- Write the SOP according to the protocol on writing a Procedure SOP in the Master SOP and use the template for a Procedure SOP attached to the Master SOP.

- Review and authorize the SOP according to the procedure in the SOP for Document Control. Store the SOP in the folder Procedure SOPs.

- Make sure that all the staff members are aware of the existence and contents of this SOP by notifying them in a weekly staff meeting. All staff members must read this SOP and sign the Read and Understand List to ensure that everybody is able to correctly decontaminate, label and transport equipment. Therefore, include the SOP in the Read and Understand List and indicate who have to read the SOP.