Quality Management

What is quality management and what is a quality management system?

A laboratory, just like any other organization, consists of numerous processes in which inputs are turned into outputs through one or more process steps. The core process of the laboratory is the primary process consisting of three stages: the pre-analytical stage (the sample is collected, received at the laboratory, registered and processed), the analytical stage (the actual laboratory test is performed and the result is recorded), and the post-analytical stage (the result is authorized, reported and archived and the sample is discarded/archived).

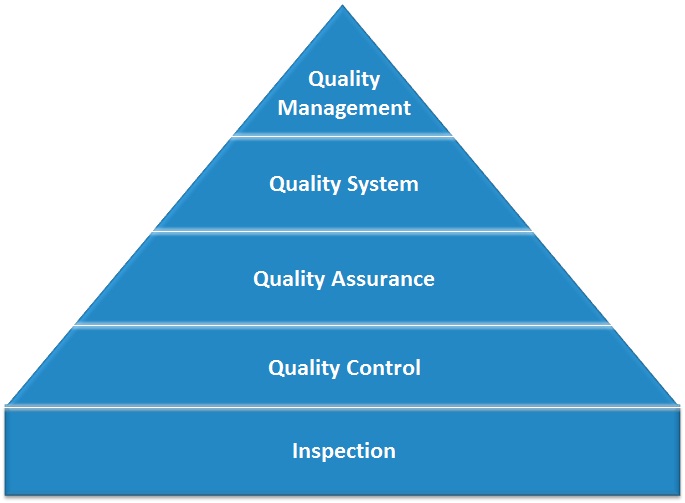

A Quality Management System affects each single process of the laboratory and consists of several layers. You can see this as a pyramid:

The basis of the pyramid consist of Inspection. This is nothing more than arbitrary (-partly subconcious-) inspection of work by the laboratory technologist him/herself. Detection of errors depend on alertness of the technologist.

Active, more structured, concious and rational inspection of process performance is called quality control. This is the implementation of control steps at strategic logical points in each process of the laboratory to monitor correct performance and quality output. This enables the laboratory to be certain that its final output, i.e. the test result, is of good quality. With quality control errors can only be detected after they have already happened.

Quality Management System

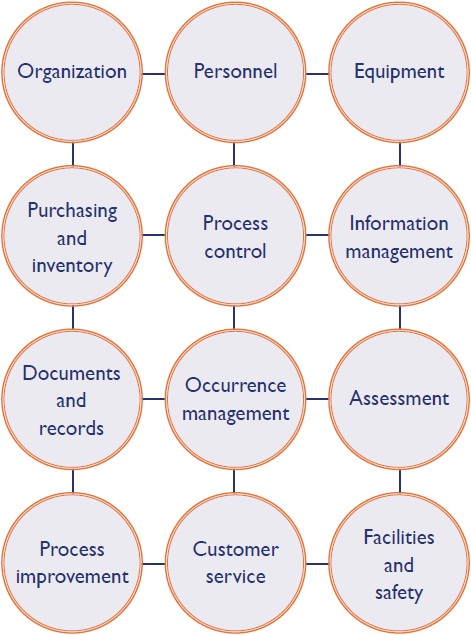

A quality management system can be described as a set of building blocks needed to control, assure and manage the quality of the laboratory's processes. A system used in this tool is the framework of 12 building blocks, called quality system essentials (QSEs).

By ensuring that all the processes related to the QSEs perform correctly, quality can be assured. For example: to control and assure quality, good personnel is necessary. The personnel members need to be adequately trained. There should be records of their training in order to be able to prove that personnel members have been trained. Each personnel member also needs to know exactly what he/she needs to do, which is achieved through job descriptions. The performance of personnel members needs to be checked through performance appraisals. Only be doing this, the laboratory can ensure that its personnel members are competent to work in a quality controlled and assured way.

Good quality equipment is also indispensable for good performance of the laboratory. For this an equipment maintenance schedule should be present. Equipment should be calibrated correctly at all times. There should also be procedures in place for when a piece of equipment is functioning incorrectly. Similarly to equipment and personnel a lot of procedures should be in place regarding all the other QSEs. Only by having that, the laboratory can manage the quality of its most important end product: the result to an examination.

The LQSI tool ensures correct implementation of all the procedures of all the QSEs, i.e. the quality management system. In this tool a lot of background information on quality management is included from the Laboratory Quality Management System training toolkit that was developed by the World Health Organization (WHO), Centers for Disease Control and Prevention (CDC) and the Clinical and Laboratory Standards Institute (CLSI). The WHO LQMS follows the QSE structure. The complete WHO LQMS toolkit can be downloaded here.

What are quality standards and guidelines?