Title

Why

The laboratory work space and facilities must be such that the workload can be performed without compromising the quality of work or the safety of the laboratory staff, other health care personnel, patients or the community. In the previous activity the biosafety levels for the facility were determined, in accordance with the risk. To achieve compliance with the requirements related to these biosafety levels, an improvement plan was developed. Besides biosafety level-specific requirements, there are also safety requirements with which all laboratory rooms need to comply. This activity aims at achieving compliance with these general (bio)safety requirements.

What

The strategy used for achieving compliance to general safety requirements for laboratories is the performanjce of a safety assessment. The checklist used for this activity can be found in annex B of ISO 15190:2003 'Medical Laboratories - Requirements for Safety'. For every noncompliance found with the checklist questions an improvement plan must be developed.

ISO 15190:2003 'Medical Laboratories - Requirements for Safety' provides a readable and complete overview of all the requirements for a medical laboratory. It is strongly advised to first read this document before conducting the laboratory safety audit as this will give you an overview of what is required regarding laboratory safety.

How & who

Biosafety Officer:

- Perform the Facility and Safety Assessment using the checklist provided in ISO 15190, Annex B.

- Report all the biosafety nonconformities noted during the Facility and Safety Assessment.

- Discuss with the laboratory manager for every nonconformity:

- The urgency of solving the nonconformity

- The solution for solving the nonconformity

- The period in which the nonconformity must be solved.

- Make action points for all the nonconformities

- Combine all action points into an action plan entitled "Facility and Safety Assessment" and put this in the Action Plans folder.

- Check on a monthly basis the timely and correct implementation of action points. If completion of certain action points is not yet done after passing of the deadline, notify the Laboratory Manager who has to ensure that the assigned person implements the action point as soon as possible.

Laboratory Manager:

- Discuss with the Biosafety Officer on the urgency of nonconformities noted during the facility and safety assessment, formulate solutions for solving the nonconformities, and define the period in which each nonconformity must be solved.

- Assist the Biosafety Officer in ensuring timely execution of action points. Check the timely and correct completion of action points during the bimonthly meetings with the Biosafety Officer. Assist also in the search for funding that may be needed to complete certain action points.

- If the Biosafety Officer indicates that certain action points are not yet implemented while their deadline has already passed, make the assigned staff member complete the action point as soon as possible.

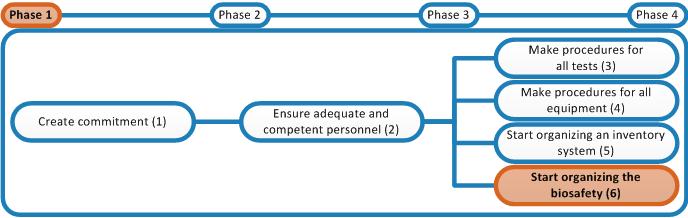

NOTE that it is not required to comply with all the requirements already at the end of phase one. It is the responsibility of the Laboratory Manager in combination with the Biosafety Officer to make sure that attention to improving safety is evenly spread over the four phases of this tool, according to his/her own estimation of what is achievable. It is important that the laboratory complies with all requirements when accreditation is requested.

Upgrading facilities and safety can be a complicated process in low and middle income countries due to resource constraints. This must be taken into account when making the improvement plan. For example: if a mechanical ventilation system for negative pressure is required because high risk activities are performed at the laboratory, efforts may already have to start in phase 1 to find funds, purchase, ship and install such a system since this process may take a long time. If the laboratory leaves commencement of this process until phase 4, it will be a disappointment in the event that the final external audit for accreditation is delayed due to the mechanical ventilation system having yet to be installed.